Eco Facts

Environmentally friendly facts with Bossklein

Bossklein has a “future first” approach when it comes to both packaging and chemical composition – if there is an equivalent raw material available that has a lesser impact on the environment then we strive to include this whenever there is an opportunity for reformulation.

Unlike many other competitor formulations that were designed decades ago, advancements in raw material chemistry now provide alternative ingredients that not are not only safer than their predecessors but are also much less harmful to the natural world.

Bossklein recognises that by making relatively small changes to the everyday items we use we can make a big impact. If we can reduce the amount of CO2 that is being released into the environment we reduce our overall carbon footprint.

Reduced plastic 5L… available now

New reduced plastic 5L container in the Bossklein infection control range.

This new addition uses 53% less plastic than the outgoing bottle, helping to reduce our carbon footprint by stopping more than 1.5 tones of new plastic from entering the supply chain each year.

This change affects all Bossklein products that offer the 5L variant including IDactiv, DAILYasp, ULTRAbio, SDactiv and SDactiv Zero and B70gel.

Recycled plastic dispenser tubs

All V-WIPE Classic tubs are now made from 35% PCR plastic.

PCR plastic is made from recycled plastic that can be widely recycled, reprocessed and then used to create brand new packaging. This gives packaging a second life and significantly reduces the amount of plastic waste.

Switching our tubs to PCR plastic saves 31.5g of new plastic from entering the supply chain for every tub produced when compared to the previous version.

Manufacturing recycled plastics also uses up to 80% less energy when compared to producing virgin plastics.

For every kilogram of recycled plastic we use, we can save up to 2.5kgs of carbon dioxide from entering the atmosphere.

Refill, reuse and repeat

V-WIPE dispenser tubs can be refilled and reused multiple times with our economical refill packs. All V-WIPE Classic and Ultra wipes utilise refillable tubs, unlike many other brands that have single use only, pre sealed tubs.

Each refill pack contains approx. 85% less plastic than a brand-new wipe dispenser tub.

Our Classic V-WIPES are also available in wipe kits of 12 x refill packs + 1 x dispenser tubs for the ultimate cost and energy saving package.

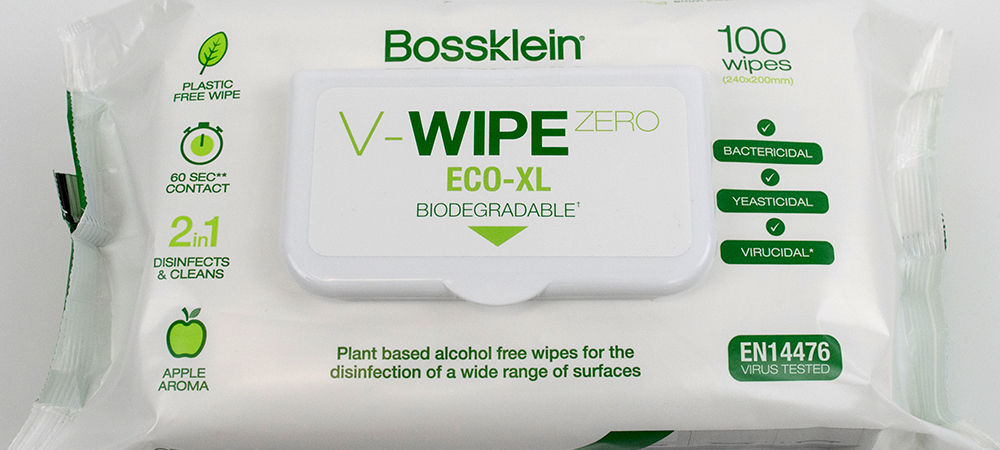

Biodegradable plastic free wipes

V-WIPE ZERO ECO-XL wipes are made from a plastic free, biodegradable material called Viscose. Viscose is a plant-based, renewable material made from responsibly sourced wood pulp.

The unique wipe material uses a 40g/m² apertured 100% viscose. Viscose is not only renewable, but sustainable when compared to synthetic petrol chemical based nonwoven types such as polypropylene and polyester.

See below for further information about the solution used inside V-WIPE ZERO ECO-XL

Fibres are sourced from world leading fibre manufacturers Lenzing and Birla, both recognised for their responsible sourcing of wood pulp. You can read more using the links below:

https://birlacellulose.com/responsible-sourcing.php

https://www.lenzing.com/sustainability/production/resources/wood-and-dissolving-wood-pulp

The process of making these fibres into a nonwoven is a process known as spunlacing where fibres are hydroentangled by water jet systems with no need for added chemical binders. This process recycles water numerous times before being discharged.

Reduced plastic wipe dispenser

The flowpack dispenser with stay fresh lid used for both V-WIPE ZERO UNIVERSAL-XL and ECO-XL wipes removes the need for a traditional dispenser tub, significantly reducing the total amount of plastic consumed.

The secure stay fresh lid ensures future wipes remain fresh and moist, ready for peak disinfection performance.

ZERO surface disinfectant solution

Our unique ZERO formulation is used in all V-WIPE ZERO surface disinfectant wipes, including ECO-XL, and also our SDactiv ZERO surface disinfectant sprays.

The solution is free from alcohol and polyhexamethylene biguanide (PHMB) – PHMB is a registered category 2 carcinogen by the European Union and utilised in many other alcohol free competitor disinfectant products.

The exclusive formulation utilises two readily biodegradable quaternary ammonium compounds (QACS) and also includes a plant-based detergent derived from natural resources and a plant based, naturally derived chelating agent.

Modern instrument disinfection

IDactiv has been designed to utilise as many eco-friendly and natural ingredients as possible to minimise the impact on the environment.

The instrument disinfectant and cleaner contains a plant-based chelating agent to attract ions that can block disinfection.

The cutting-edge formulation also contains no alcohol or chlorides which can both cause corrosion. IDactiv benefits from utilising both a biodegradable corrosion inhibitor and detergent, while also including naturally occurring amino acids.

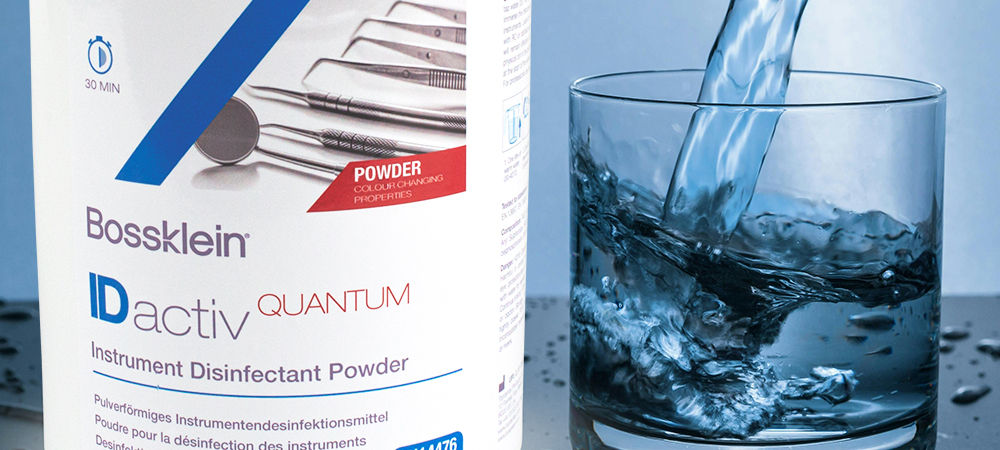

Clean disinfection power

Both the Bossklein IDactiv QUANTUM instrument disinfectant powder and IMPactiv P impression disinfectant powder use peracetic acid as their primary active ingredient. This creates a powerful disinfectant and cleaner.

Peracetic acid is not activated until mixed with water and one of the most eco-friendly biocides available. After use the only waste product produced by peracetic acid degrades is just water and oxygen.

Both products also contain biodegradable corrosion inhibitors and a biodegradable detergents.

Natural high performance

Due to the almost constant need for clinical staff to keep hands disinfected throughout the day, it is vital that the skin remains intact after repeated exposure high levels of alcohol.

Bossklein B70gel contains plant-based Aloe Vera to actively moisturise the skin along side naturally derived glycerine and Vitamin E.

The unique formulation is dye free, allergen free and hypoallergenic ensuring maximum disinfection performance without causing damage to skin.

Universally recyclable

The robust steel construction of the Bossklein UNIoil canister not only ensures the Universal Handpeice Oil lubricant product arrives protected and as intended, but it is also universally recycled alongside other common recycled materials.

Steel is 100% recyclable and can contain up to 25% already recycled steel. It is one of the easiest materials to recycle.

Kind to Aspirator systems

Bossklein DAILYasp is used to disinfect all types of aspirator/suction system.

The 2% concentrated disinfectant and cleaning solution is one of the most powerful products of its type on the market and one of the most efficeint delivery methods. Each 5L bottle contains enough concentrate to make 250 litres of useable solution.

All DAILYasp bottle sizes available (1L, 2.5L and 5L) are easily recyclable after use alongside other items in general recycling waste.

Concentration is the key

Bossklein utilises economical concentrated solutions for the majority of our infection control range.

Many of our products take advantage of low percentage dilution ratios such as 2% or 20ml to 1L. This means a single 5 litre refill container can make up to 250 litres of high performance disinfectant and cleaning solution.

All dental and medical facilities have access to fresh, clean water so by allowing end users to dilute their own solutions we can help reduce the total amount both transported and stored – this can help to reduce overall carbon emissions.